HDPE – Polythene

Polyethene is one of the most commonly used synthetic materials worldwide. Its use is widespread over different industries. This synthetic material makes it possible to package foods in a favorable way, leading to an extension of its shelf life.

Polyethene has a lot of different product families. Its standard material is available in low density (LDPE), high density (HPDE), medium density (MDPE), and linear low density (LLDPE). We make many synthetic product parts out of this material.

Laser cutting polythene

Polyethene is suitable for laser cutting up to a thickness of 10 millimeters. This is also the case for aslant polyethene, which can be cut up to a thickness of 15 millimeters. The quality is excellent.

Why polyethene?

- Thermoplastic properties (HDPE can be welded perfectly)

- Robustness (HDPE is strong and tough)

- High electrical resistance (HDPE is not a conductor)

- Negligible water absorption

- UV resistant

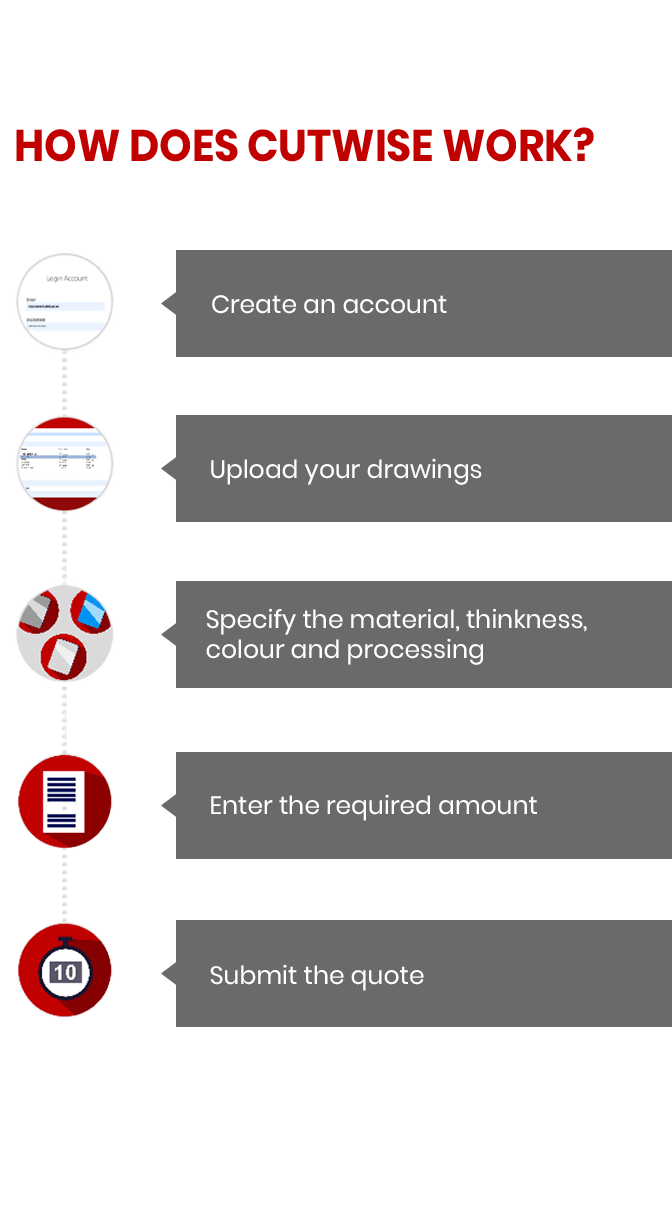

A CUSTOM QUOTE FOR LASER CUT INTERMEDIATE PRODUCTS INSTANTLY

Would you like to receive a custom quote for laser cut intermediate products within 10 seconds?

It’s possible now thanks to CutWise by BMTEC.