Cast or extracted acrylate

We work on cast as well as extracted polymethyl methacrylate (PMMA). PMMA is better known under the trade names Plexiglas, Perspex, and Altuglas. This material is used a lot in the sign and advertisement industry. Due to a number of strong properties, acrylate is also often used in ship and yacht construction. Polymethyl methacrylate also has many advantages as opposed to glass. The material is lighter and more transparent. We have already used it as a raw material for our clients.

Laser cutting PMMA

Polymethyl methacrylate is easily modified by laser machines. We can supply this synthetic material from our own stock. BMTEC works on polymethyl methacrylate up to a 30 milimetre width. There is also a myriad of color combinations with acrylate.

Hard coating for acrylate.

We also supply polymethyl methacrylate with a hard coating. This hard-coated acrylate is very scratch resistant.

Cast or extracted acrylate

We work on cast as well as extracted polymethyl methacrylate. The cast quality is virtually de-energized, which makes it easy to modify and bond. The extruded quality, however, has more energy. In addition, there is a large difference in price between the materials. The coated material is pricier than the extruded one.

Why PMMA?

- Shockproof

- UV resistant

- Lighter than glass

- More light passes through than with glass

- Very suitable for laser cutting

- Easily produced in all kinds of shapes

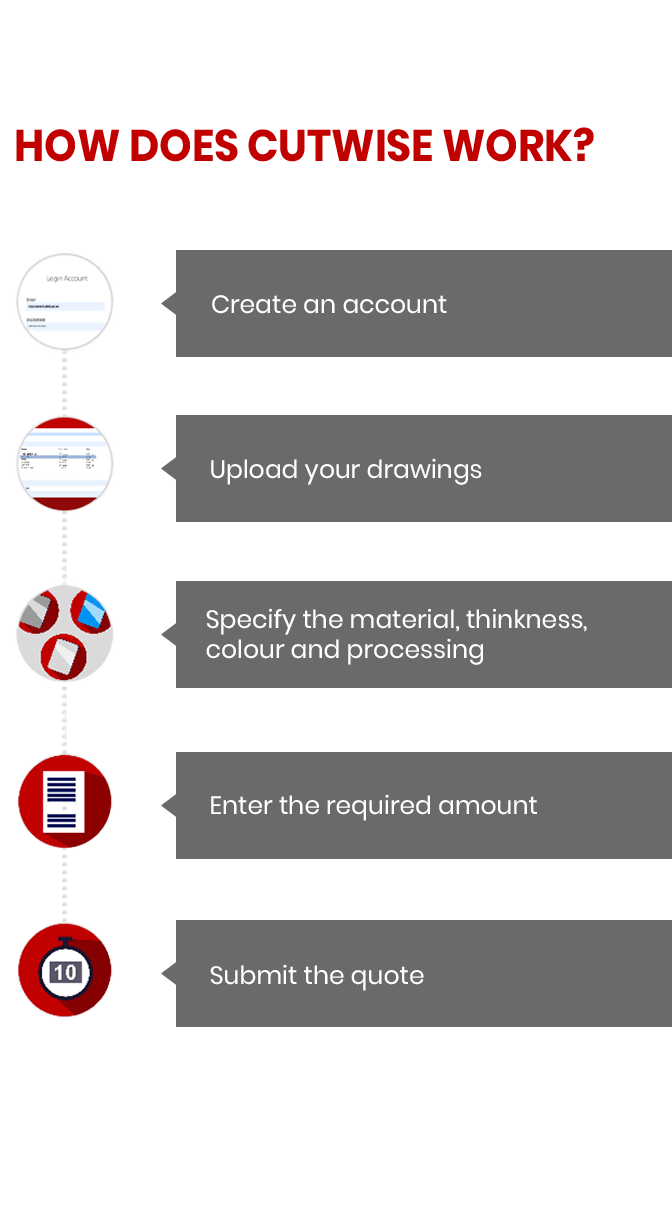

A CUSTOM QUOTE FOR LASER CUT INTERMEDIATE PRODUCTS INSTANTLY

Would you like to receive a custom quote for laser cut intermediate products within 10 seconds? It’s possible now thanks to CutWise by BMTEC.